PTL (Pick-To-Light) Intelligent Picking System

How can production lines and warehouse management accelerate manual picking processes and enhance operational efficiency? Integrating Pick-To-Light shelving storage offers an efficient and intuitive solution.

Pick-To-Light is an intelligent system designed to assist manual picking by guiding personnel through electronic displays and indicator lights, enabling quick and accurate identification of items. This significantly improves picking speed and accuracy.

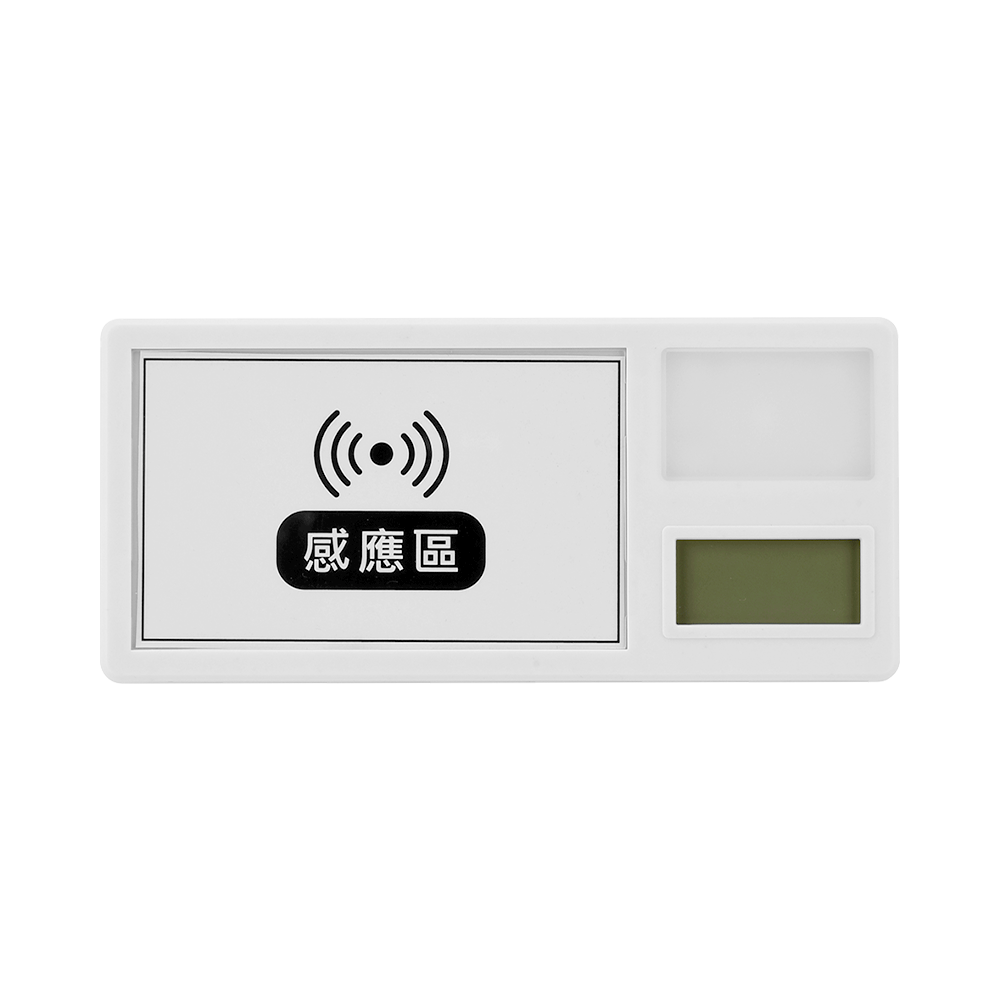

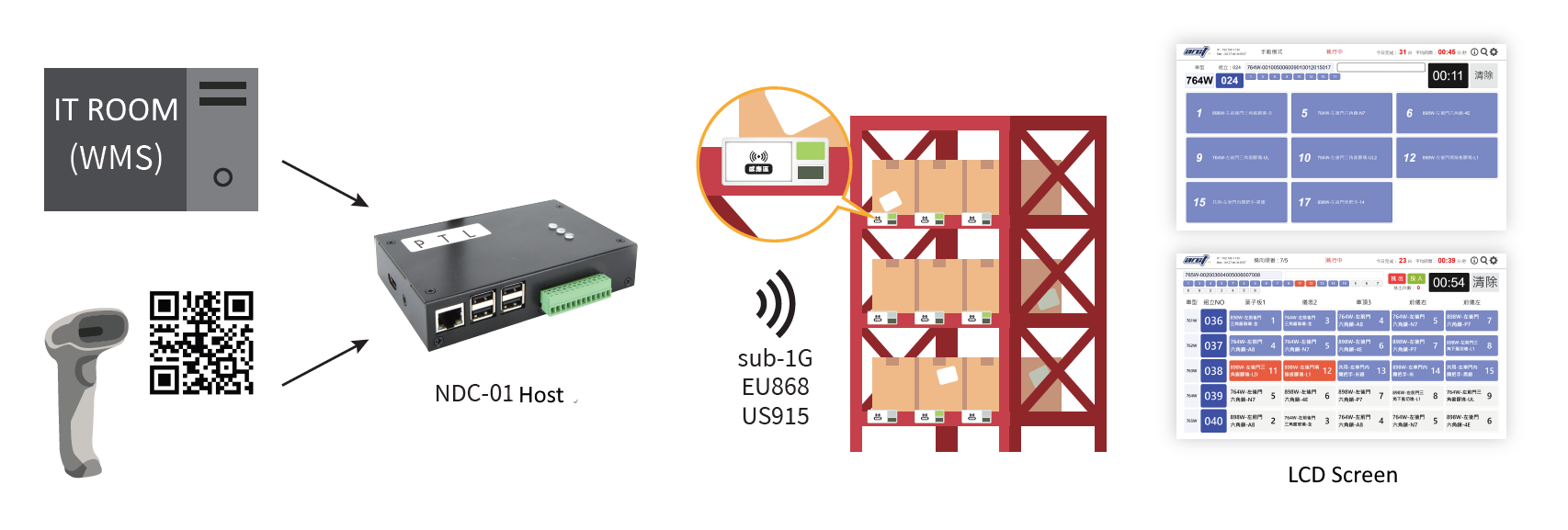

The system supports manual operation and can seamlessly integrate with Warehouse Management Systems (WMS). Upon order generation, the electronic display at the corresponding storage location lights up, clearly indicating the items and quantities to pick. Operators follow these instructions to complete picking and confirmation, thereby accelerating task completion.

Applications and Key Advantages

Pick-To-Light is especially suited for environments demanding fast shipment, high-frequency assembly, or strict logistics timelines. It greatly enhances operational efficiency, reduces errors, and optimizes warehouse workflows, helping businesses build smart warehousing and strengthen logistics competitiveness.

If your production line or warehouse seeks an efficient picking solution, the PTL (Pick-To-Light) system is your ideal step toward intelligent logistics.

The New Revolution in Efficient Picking — How the Pick-To-Light Intelligent Picking System Works

PTL (Pick-To-Light) System Overview

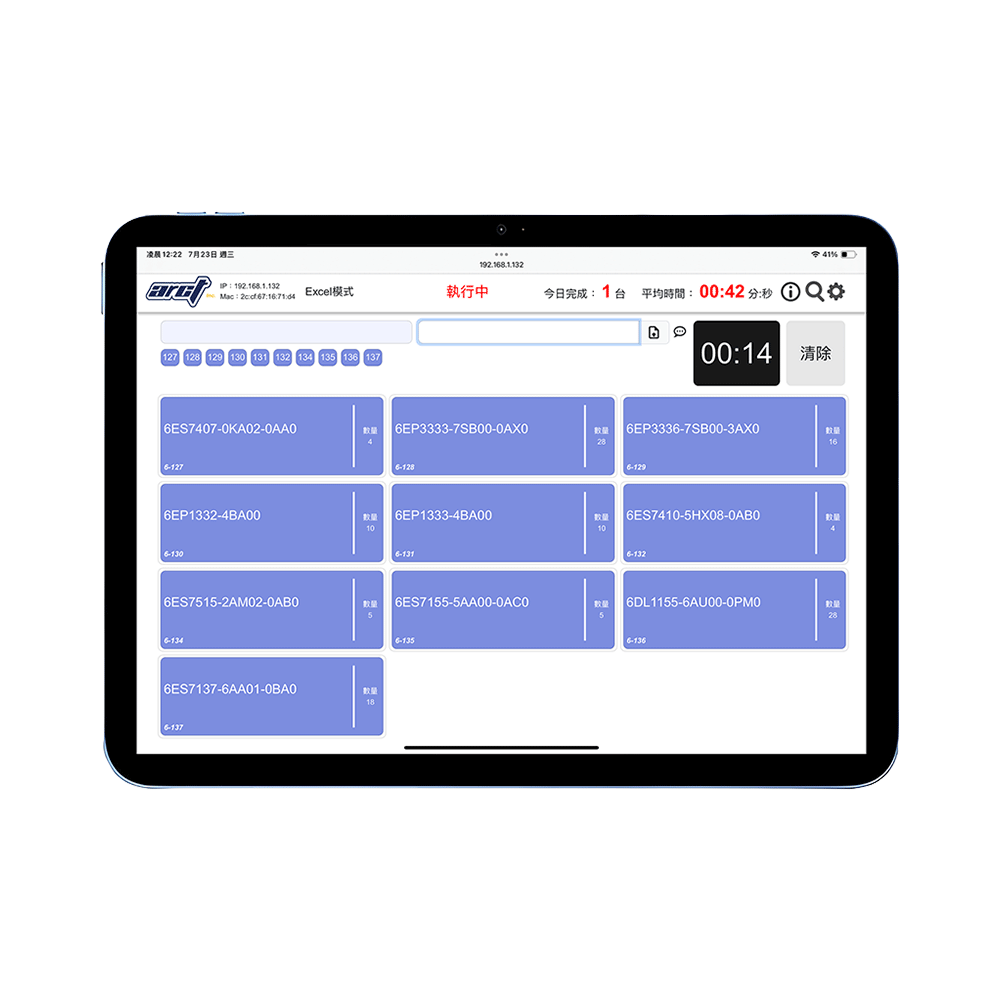

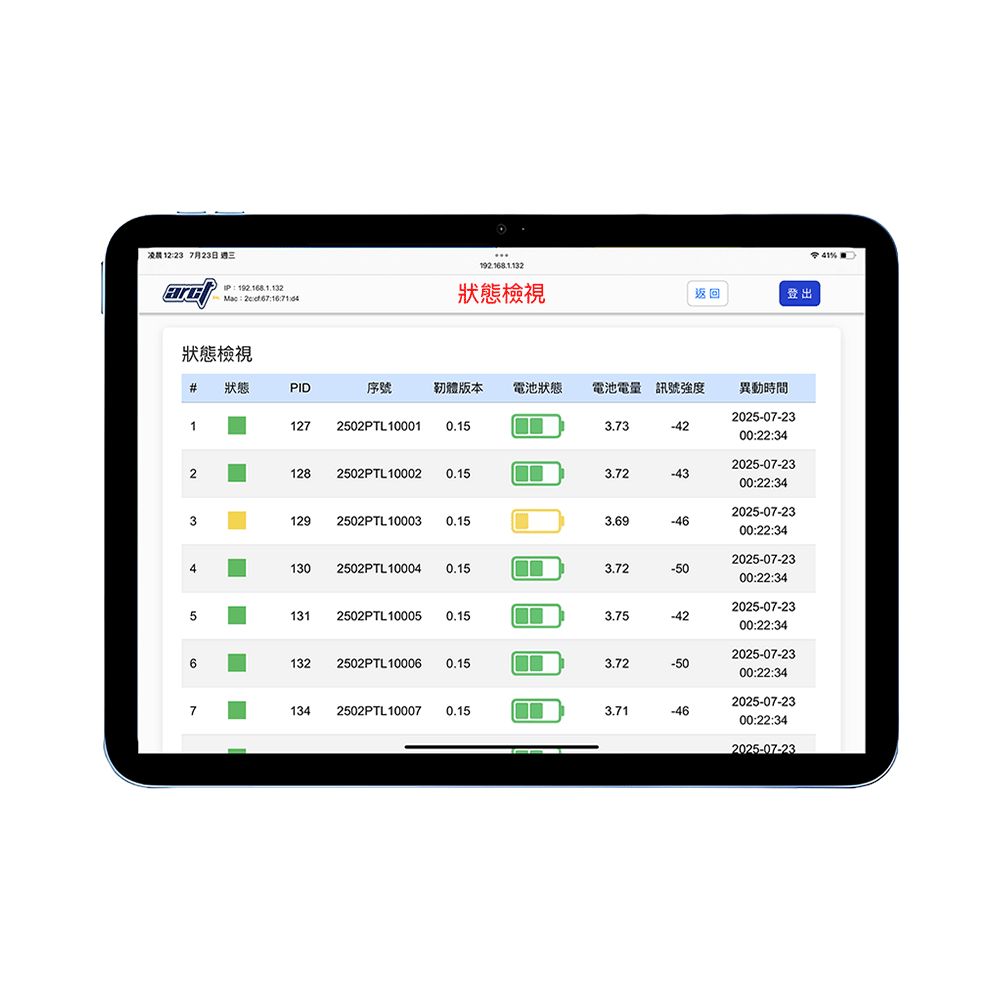

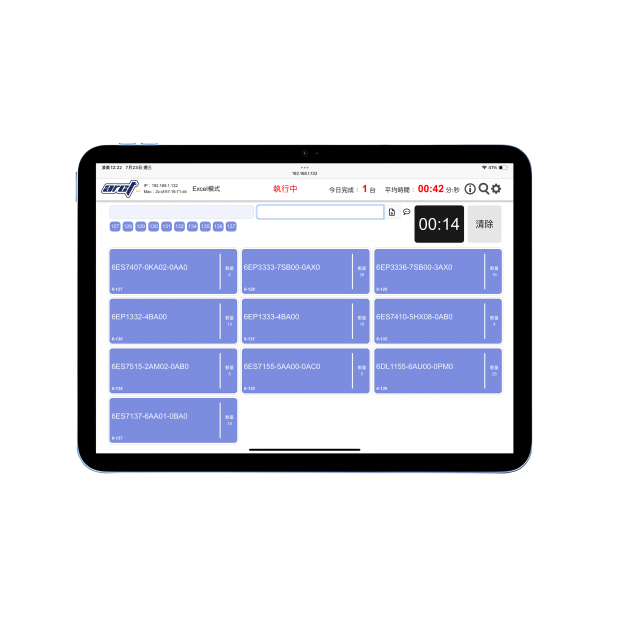

The PTL system uses LED indicator lights and LCD displays to provide picking personnel with fast and intuitive picking guidance, significantly improving operational efficiency and accuracy. Display devices are installed at each workstation and picking aisle and are integrated with the Warehouse Management System (WMS) to instantly track inventory quantity and product types at each storage location.

Automated Picking Process

-

Order Generation: When an order is created manually or automatically, the shelving system receives commands and highlights the items to be picked.

-

Light Guidance: Indicator lights at the corresponding locations illuminate, showing the storage position and quantity required, allowing pickers to quickly locate the correct items and avoid mistakes.

-

Pick Confirmation: After picking the required quantity, personnel confirm completion via a magnetic wristband sensor.

With the Pick-To-Light system, your warehouse can achieve faster picking speeds, lower error rates, and more precise inventory management—moving your logistics operations toward smarter, more efficient workflows.

Why Choose PTL (Pick-To-Light)?

The Pick-To-Light intelligent picking system plays a crucial role in modern logistics operations by leveraging advanced light signals and digital management technologies, delivering six core advantages:

-

Accelerate Picking and Boost Productivity:

Quickly guide pickers to correct locations, reduce unnecessary movement, and significantly save time. -

Optimize Warehouse Management for Orderliness:

Digital processes reduce human errors and keep storage areas organized, improving management efficiency and logistics flow. -

Reduce Errors and Improve Order Accuracy:

Precise light indications minimize picking errors, ensuring timely and accurate order fulfillment. -

Lower Labor Costs and Enhance Customer Satisfaction:

Faster, more accurate picking reduces workforce requirements and operational costs, improving customer experience. -

Ideal for Small Item Handling:

Especially suited for small, hand-operated products to maximize picking efficiency. -

Enhance Overall Logistics Performance:

Intelligent workflow control helps companies achieve efficient fulfillment and strengthen logistics competitiveness.

Pick-To-Light: Faster, More Accurate, and Smarter Picking!

PTL-100 Light Indicator Specifications

| Specification | Details |

|---|---|

| Frequency | 868–932 MHz |

| Data Rate | 10,000 bps |

| Modulation | FSK |

| Communication Protocol | ARCT Protocol |

| Channel Bandwidth | 50 KHz |

| Sound Volume | 80 dBa @ 10cm |

| Dimensions | 110 (L) x 56 (W) x 18 (H) mm |

| Charging Voltage | 5V DC |

| Charging Current | 50–200 mA |

| Charging Time | Approx. 6–10 hours |

| Battery | 1.2V Ni-HM AAA x 3 pcs |

| Standby Time | 270 days (alkaline battery) / 180 days (Ni-HM) |

| Usage Time | 90 days (50 activations/day, 30 sec each) / 30 days (400 activations/day, 30 sec each) |

| Certifications | FCC, CE, NCC |

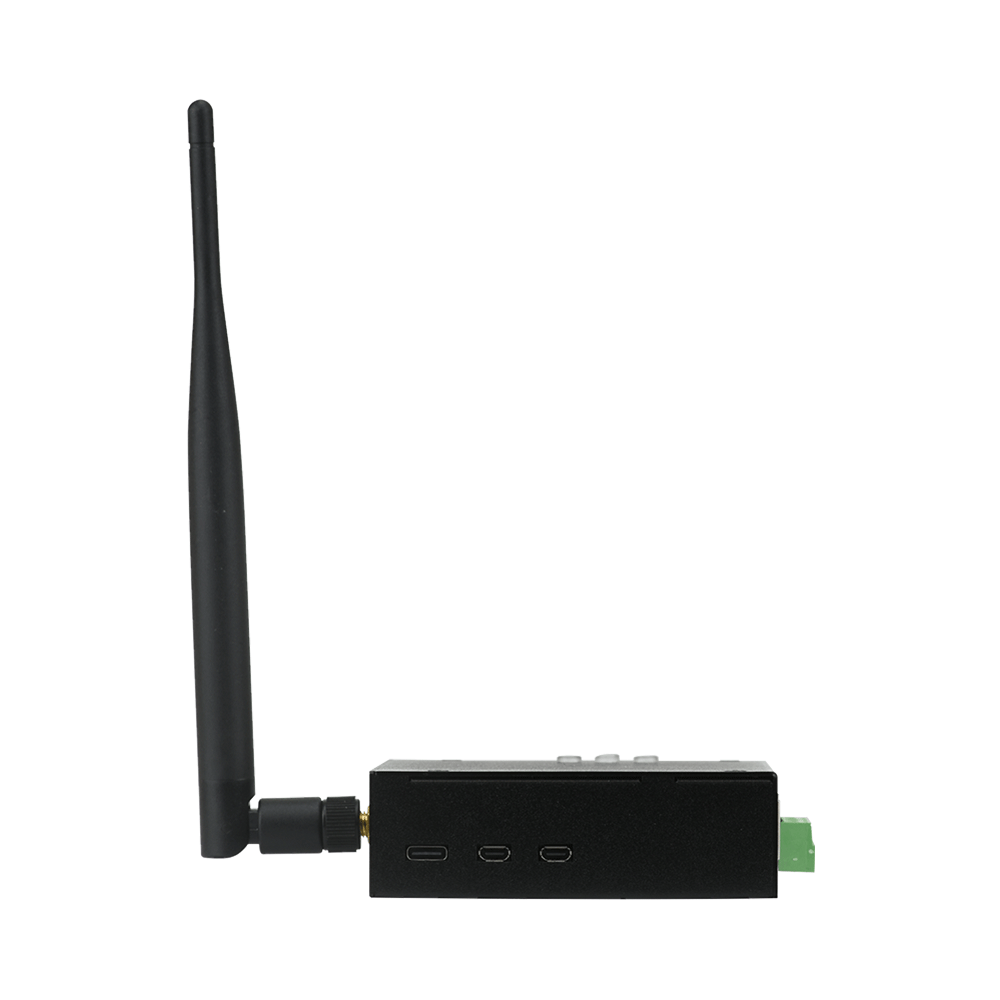

NDC-01 Pro - 4 Relay Port RF Specifications

| Specification | Details |

|---|---|

| Frequency | 868–932 MHz |

| Data Rate | 12K bps |

| Modulation | FSK |

| Output Power | 0.1 Watt |

| Modulation Bandwidth | +/- 12 KHz |

| Channel Bandwidth | 200 KHz |

| Relay Switch Voltage | 250VAC, 220VDC |

| Max Relay Load | 500VA, 440W |

| RF Output Connector | SMA(F) |

| Frequency Stability | 2 ppm at -10℃ to +60℃ |

| Power Consumption | Standby: 200mA; Transmit: 500mA |

| Operating Environment | 0℃~+50℃; 20% RH to 90% RH (no condensation) |

| Dimensions | 138 (W) x 90 (D) x 30 (H) mm |

| Weight | 450 g (excluding power adapter) |

Mainboard Specifications

| Component | Details |

|---|---|

| SoC | Broadcom BCM2712 |

| CPU | 2.4GHz quad-core 64-bit (16nm) Arm Cortex-A76 (ARM v8) |

| GPU | VideoCore VII GPU @ 800 MHz, supports OpenGL ES 3.1, Vulkan 1.2 |

| Video Output | Dual 4Kp60 HDMI® display output with HDR support |

| Memory | LPDDR4X-4267 SDRAM, 4GB |

| USB Ports | 2 × USB 3.0 (5Gbps simultaneous), 2 × USB 2.0 |

| Ethernet | Gigabit Ethernet with PoE+ support (requires separate PoE+ HAT) |

| Power Supply | 5V/5A DC via USB Type-C |